Why Choose Stainless Steel Woven Wire Mesh for Your Projects?

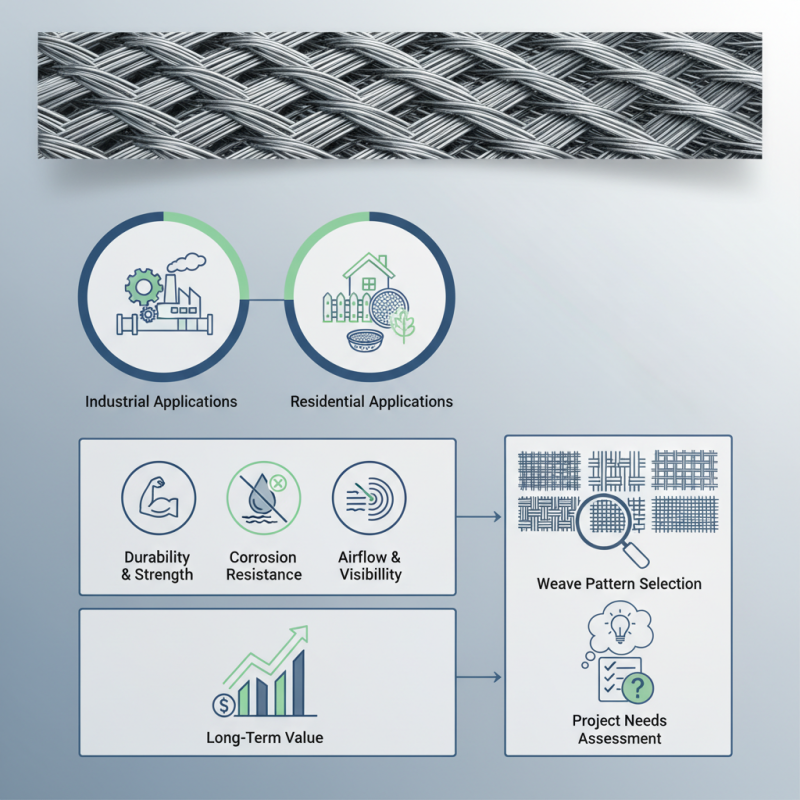

When considering materials for various projects, stainless steel woven wire mesh stands out as a top choice. Its durability and resistance to corrosion make it ideal for both industrial and residential applications. Many industries utilize this versatile mesh due to its strength and aesthetic appeal.

stainless steel woven wire mesh is not only functional but also visually attractive. It can be used in architectural designs, filtration systems, and even as protective barriers. The mesh allows for airflow and visibility while providing strong support. However, some may hesitate due to its initial cost. The investment pays off in durability, reducing long-term replacement needs.

While this material has numerous benefits, it is essential to acknowledge that selecting the right weave pattern is crucial. Different projects require different characteristics, and not all stainless steel woven wire meshes are created equal. Buyers must reflect on their specific needs and applications to ensure optimal performance.

Advantages of Stainless Steel Woven Wire Mesh in Various Applications

Stainless steel woven wire mesh offers numerous benefits for various applications. Its strength and durability make it a favored choice in industries like construction, food processing, and filtration. According to a recent industry report, stainless steel mesh can withstand extreme temperatures and corrosive environments. This resilience translates to lower maintenance costs over time, making it a cost-effective solution.

One major advantage is its versatility. It can be used in architectural designs, security fencing, and even industrial equipment. Stainless steel’s non-reactive nature makes it ideal for food processing. A study indicated that using stainless steel mesh can reduce contamination risks by over 40%. This fact emphasizes its reliability in ensuring safety and quality.

Tip: When selecting stainless steel woven wire mesh, consider the wire diameter and mesh size. These factors will affect strength and filtration capacity. Choosing the right specifications is vital for your project's success.

However, one must reflect on the environmental impact of production. While stainless steel is recyclable, the energy used in manufacturing can be significant. It's essential to evaluate the entire lifecycle of materials used in your project. Balancing durability with sustainability can lead to better choices for future projects.

Key Properties of Stainless Steel That Enhance Durability and Longevity

Stainless steel woven wire mesh is a preferred choice in many projects due to its impressive durability and longevity. The material boasts high resistance to corrosion, making it suitable for harsh environments. According to industry reports, stainless steel can last up to 50 years under proper conditions. This longevity minimizes maintenance costs over time.

Key properties of stainless steel contribute to its efficiency. It has a high tensile strength, which means it can endure substantial stress without breaking. Additionally, it is non-reactive, ensuring that it will not leach harmful substances. This makes it an excellent option for food processing or medical applications.

Tip: Consider using stainless steels with low carbon content for better weldability. This can improve the overall structural integrity of your mesh. Another tip is to select a mesh size that best fits your needs. Various sizes can affect filtration efficiency and airflow. Proper selection impacts the effectiveness of your project.

Applications of Stainless Steel Woven Wire Mesh in Different Industries

Stainless steel woven wire mesh is crucial in various industries. Its durability and resistance to corrosion make it ideal for many applications. For example, in the food industry, this material is often used in conveyor systems. It's easy to clean and maintains hygiene standards. However, improper cleaning can lead to contamination, which is a serious concern.

In construction, stainless steel wire mesh enhances structural integrity. It’s used in concrete reinforcement and safety barriers. Yet, mistakes in installation can compromise safety. Proper mesh selection is vital. In the automotive sector, manufacturers use it for filtration systems. It ensures efficiency but can fail if not maintained correctly. Regular checks are essential to prevent breakdowns and costly repairs.

Each industry sees unique benefits from stainless steel woven wire mesh. However, it’s important to consider potential shortcomings. Regular maintenance, proper installation, and careful selection are key factors for success.

Why Choose Stainless Steel Woven Wire Mesh for Your Projects? - Applications of Stainless Steel Woven Wire Mesh in Different Industries

| Industry | Application | Benefits |

|---|---|---|

| Food Processing | Sieving and filtering | Corrosion resistance, easy to clean |

| Pharmaceutical | Containment and separation | Non-reactive, durable |

| Construction | Reinforcement and support | Strength, longevity |

| Mining | Screening and filtration | High strength, wear resistance |

| Architecture | Decorative elements | Aesthetic appeal, corrosion resistance |

| Automotive | Grilles and filters | Durability, lightweight |

Comparative Analysis: Stainless Steel vs. Other Wire Mesh Materials

Stainless steel woven wire mesh stands out when compared to other materials, especially in durability and corrosion resistance. Industry reports show that stainless steel can withstand harsh environments. For example, it resists oxidation and rust, making it ideal for outdoor applications. In contrast, materials like aluminum or plastic tend to degrade faster and may require more frequent replacements.

When considering strength, stainless steel is often preferred in demanding applications. It has a higher tensile strength than many alternatives, providing better support in construction and industrial settings. Studies indicate that stainless steel woven wire mesh has a tensile strength approximately three times greater than that of standard plastic mesh. This difference is crucial for projects that require reliable structural integrity.

Cost is another factor to consider. Stainless steel may have a higher upfront cost than other options. However, its longevity and low maintenance needs can result in lower lifecycle costs. It's important to weigh initial expenses against long-term value. Many projects benefit from the initial investment in stainless steel, though budget constraints might lead some to choose cheaper materials that won't last as long. Acting in haste can lead to regrettable replacements down the line.

Cost-Effectiveness and Maintenance Benefits of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh stands out due to its cost-effectiveness and maintenance benefits. This material resists corrosion and offers durability, enhancing its long-term value. A study by the International Wire and Wire Products Institute indicates that stainless steel mesh lasts 2-3 times longer than its plastic counterparts. This longevity makes it a wise investment for projects needing reliable performance.

Routine upkeep of stainless steel mesh is minimal. Regular cleaning with a mild detergent will keep it looking new. According to recent reports, proper maintenance can extend mesh life by 30%. This is especially significant in environments prone to harsh conditions. Keeping maintenance simple saves both time and money.

Tips: Always consider the specific environment where the mesh will be used. Assess factors such as humidity and chemical exposure. Choosing the right mesh can save costs over time. Investing in higher quality may seem daunting but pay off significantly in longevity and performance.